42STH38 NEMA-17 Bipolar 48mm Stepper

USD $19.95

This motor is a larger NEMA-17 motor that produces 3600g-cm of holding torque.

DESCRIPTION

Stepper motors are different from DC motors in that they have to be pulsed to move in set increments. That means you can't simply hook them up to a power supply to make them go, but they have other advantages, like accurate positioning (1 pulse=1 increment of movement), and lots of low-speed torque (ability to twist things). The flip side is that they are power-pigs, but ya gotta love this sort of pig!

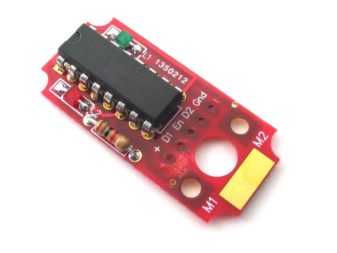

Sourced by Phidgets, this larger 3324 NEMA-17 stepper motor produces a 3600g*cm (49.99in*oz) of holding torque. To control this type of motor you'll need a circuit that has 4 or more MOSFETs, a Dual H-bridge, or a specifically designed Stepper driver.

If you're connecting it to a 1063 - PhidgetStepper Bipolar 1-Motor or similar controller, use this table to connect the motor wires to the board connectors to get clockwise rotation. To wire for counter-clockwise rotation, swap the Red and Blue wires. Please note: Connecting the motor directly to a power supply will destroy the motor and void the warranty. If you want to check your motor make sure it is connected to a constant current/chopper drive controller.

Wiring Guide

- Board Connector A is Black

- Board Connector B is Green

- Board Connector C is Red

- Board Connector D is Blue

Note: This is not the internal wiring of the stepper which is usually has A & C and B & D labels tied together, but to be clear the Black & Green wires are connected to one coil in the motor and Red and Blue the other. Datasheet available under documentation tab.

Specifications

- NEMA-17 Bipolar 4-wire

- Step Angle: 1.8°

- Step Accuracy: +/-5%

- Holding Torque: 360000g-cm / 49.99 oz-in

- Maximum Motor Speed: 1000 RPM

- Recommended Voltage: 24 VDC

- Coil Resistance: 1.7 Ohms

- Rated Current: 1.7 A

- Phase Inductance: 3.2mH

- Mounting Plate Size: NEMA-17

- Shaft Diameter: 5mm

- Rear Shaft Diameter: 3.9mm

- Shaft Length: 24mm

- Rear Shaft Length: 12mm

- Weight: 289g

- Number of Leads: 4

- Lead Length: 300mm

Note: Make sure to unplug the power cord from your driving circuit before switching wires around.

RESOURCES & DOWNLOADS

REVIEWS

Solarbotics, Ltd. is not responsible for misprints or errors on product prices or information. For more information, please see our Terms and Conditions.

Warning: This product contains chemicals known to the State of California to cause cancer and birth defects or other reproductive harm.

Please visit www.P65Warnings.ca.gov for more information. This item was manufactured prior to August 31, 2018.