The Solarbotics Solar Marble Machine Kit

USD $29.70

Marble Motion kit, enabled by Solarengine technology that keeps on moving even in low indoor light!

DESCRIPTION

Here's the new video of the complete Marble Machine in action:

We've been big fans of Mr. Raynsford (of "Just Add Sharks") and his work since he started the 365 lasercut projects in 365 days challenge. One of the projects featured there was the marble machine, something we really thought was a cool project, and so we worked with him to bring you the Solarbotics edition - solar powered!

Our Solarengine circuit stores the light from the solar cell, and releases it in an occasional pulse that drives the mechanics. In sunlight, the motor will pulse every few seconds, and drop a ball every half minute. In indoor light, motor pulses decrease to every few minutes (be patient). But you can always use the hand crank to manually advance the marble wheel.

This kit requires basic soldering tools (soldering iron, solder), a Phillips #1 screwdriver, and a small amount of white glue.

Features:

- Easy to build, with engraved building notes

- Solar-powered or hand-crank operation

- Operates in indoor light!

- 3/8" steel balls

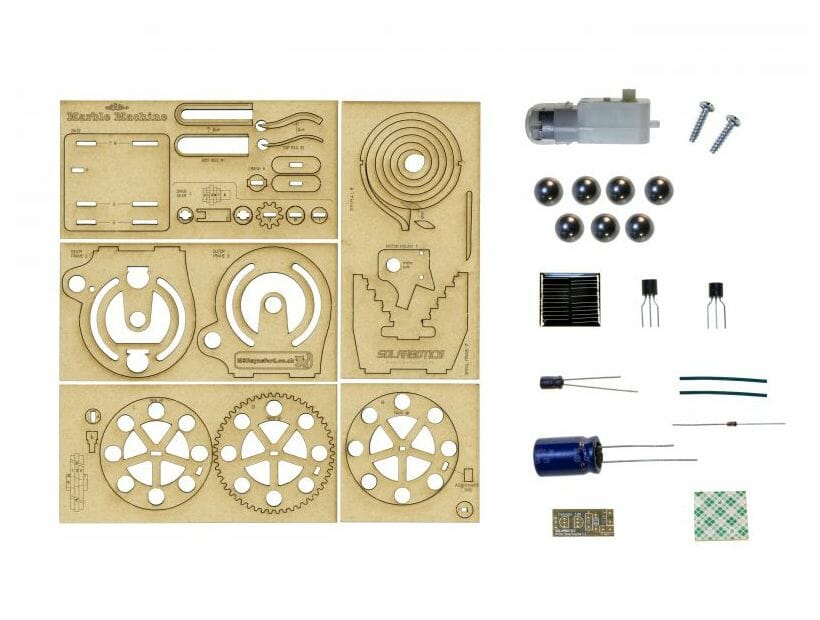

Each kit includes:

1 x Set of laser-cut Fiberboard parts

1 x GM9 motor

2 x #4x½" screws

7 x 3/8" steel Balls

1 x 4700µF capacitor

1 x SCC3733 Solar Cell

1 x PN2222A transistor

1 x MCP112 trigger

1 x Double-sided sticky tape

1 x 0.47µF capacitor

2 x 2-conductor wire

1 x Diode

1 x Solar Engine circuit board

Final assembly - wooden frame:

RESOURCES & DOWNLOADS

Additional information

| Weight | 0.35 kg |

|---|---|

| Dimensions | 23 × 13 × 3 cm |

REVIEWS

Solarbotics, Ltd. is not responsible for misprints or errors on product prices or information. For more information, please see our Terms and Conditions.

Warning: This product contains chemicals known to the State of California to cause cancer and birth defects or other reproductive harm.

Please visit www.P65Warnings.ca.gov for more information. This item was manufactured prior to August 31, 2018.