So, as usual, we have some new product Friday goodness, but first we have a few questions for you to answer. Do you live in, around, or near Vancouver? Do you like weird and fantastical projects? Do you consider yourself a DIY type of person? Do you own a Space Armadillo named Norm, that you […]

Heated Car Seat Teardown and Repair

Here's a little makeover of an inexpensive aftermarket car seat heating pad that stopped working.

Designed to activate and warm up when sat upon, the electronics face a fair amount of abuse: since the seat is a soft frame, the wires inside constantly move and flex with the body. They are also subject to harsh temperature changes with frequent (very) cold weather heating and cooling cycles, adding to a situation ripe for a malfunction, which happened to one of our staff when he couldn't warm up his tush one cold Canadian morning...

Dragging it into the lab, we peeled back the covers to discover the usual and not-so-usual suspects.

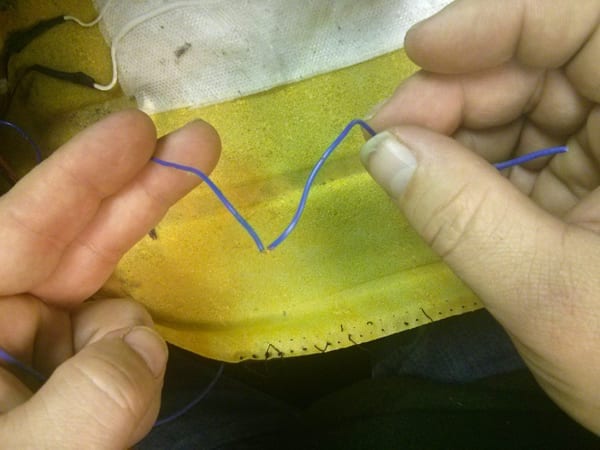

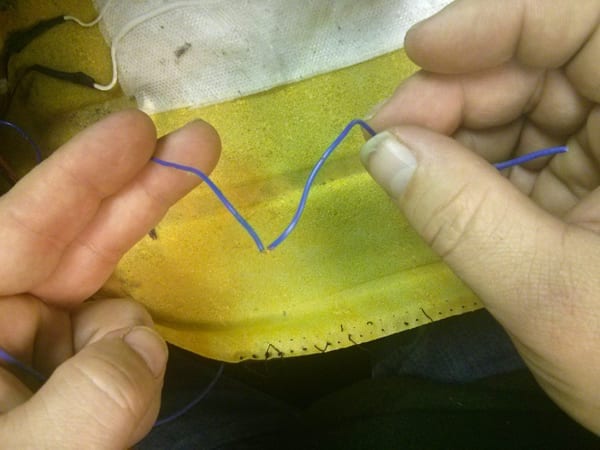

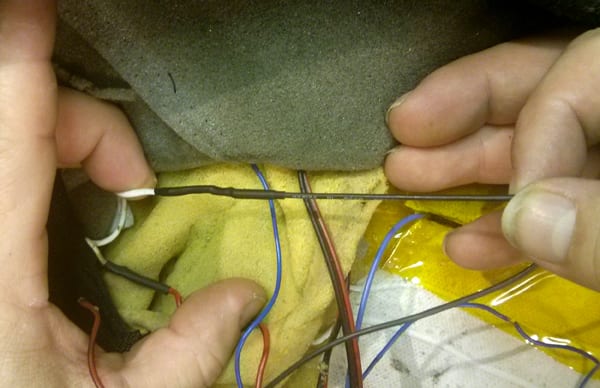

Broken wires:

The old wires had a PVC jacket that had dried out and cracked.

The wires would then flex at these cracks and break:

We replaced those wires with our GroovyNoodle silicone wire, which is able to resist flexing and temperature fluctuations very well.

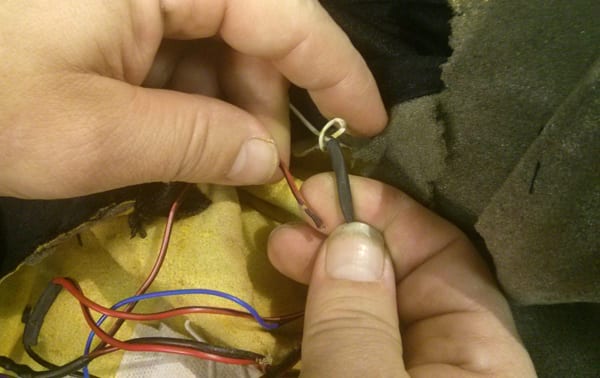

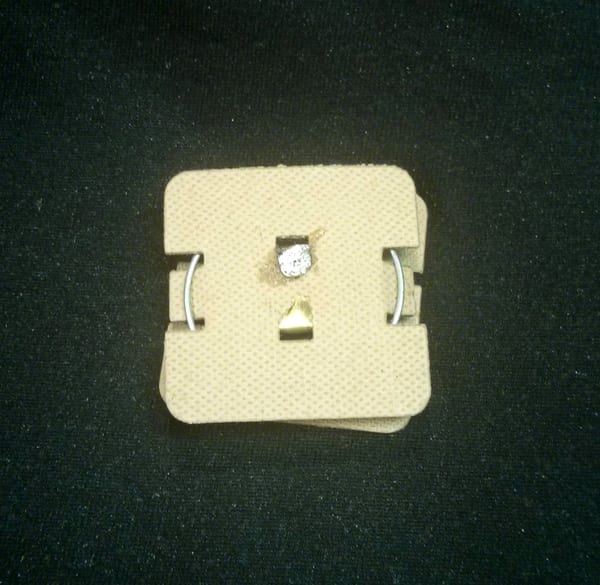

Sketchy Safety?

Here's a picture of the sketchy activation switch we found inside the bottom part of the seat. It's designed to close when under "bum load", and directly pass power to the heating coils. We're not experts at auto-grade accessory manufacturing, but we were surprised that it wasn't a logic "bum-detected" switch that triggered a suitable relay or FET elsewhere. And the lack of a thermal reset fuse surprised us.

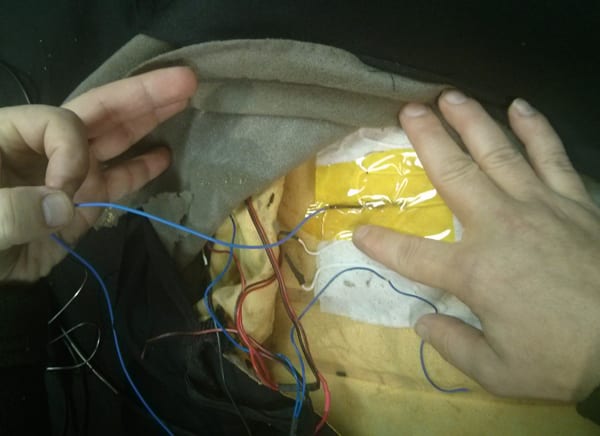

Repaired

All broken wires replaced! Almost all the PVC jacket wire had cracked and disintegrated, so we replaced it with our better-quality GroovyNoodle silicone wire. This wire is extremely flexible, high strand count, and a temperature-ignoring silicon jacket. Perfect for inside this car seat heater.

All necessary repairs and upgrades were done just in time for the next stretch of (very much) cold Canadian winter.

MORE POSTS

Today is Friday, and we are announcing a range of parts that might be helpful in your projects: Teensy-LC USB Development Board $11.65 Teensy-LC delivers an impressive collection of capabilities to make modern electronic projects simpler. Infrared Receiver 2.5-5.5V 38kHz $1.40 Compact IR Receiver for sensor applications. 2xAAA Battery Holder with Cover and Switch $1.50 […]

A little while ago we received an email from an observant Mr. Pavel Ryabinkov, the site-admin of www.myROBOT.ru, who was asking us to relay a question to Mark Tilden: Could you answer, can it be considered the official date of birth BEAM-robotics November 10, 1989?I was basing this question on the message Brian O. Bush: […]

Terribly sorry about the outage over the last day and a half. Somebody at the hosting company missed their morning cup'o'coffee, and missed a setting for our website. Be assured, we're still up and running 100% (other than the website...).

Solarbotics, Ltd. is not responsible for misprints or errors on product prices or information. For more information, please see our Terms and Conditions.

Warning: This product contains chemicals known to the State of California to cause cancer and birth defects or other reproductive harm.

Please visit www.P65Warnings.ca.gov for more information. This item was manufactured prior to August 31, 2018.