Jerome, our squiggly-bearded intern from many moons ago that created the BeetleBot, just pointed us towards this totally pimpin' pinewood derby car. The author from sliptonic.com shows how he made his sweet lowrider with hydaulic(esque) action by using a small micro-servo for each wheel, an Ardweeny for brains, and a 9V battery for power. The […]

Heated Car Seat Teardown and Repair

Here's a little makeover of an inexpensive aftermarket car seat heating pad that stopped working.

Designed to activate and warm up when sat upon, the electronics face a fair amount of abuse: since the seat is a soft frame, the wires inside constantly move and flex with the body. They are also subject to harsh temperature changes with frequent (very) cold weather heating and cooling cycles, adding to a situation ripe for a malfunction, which happened to one of our staff when he couldn't warm up his tush one cold Canadian morning...

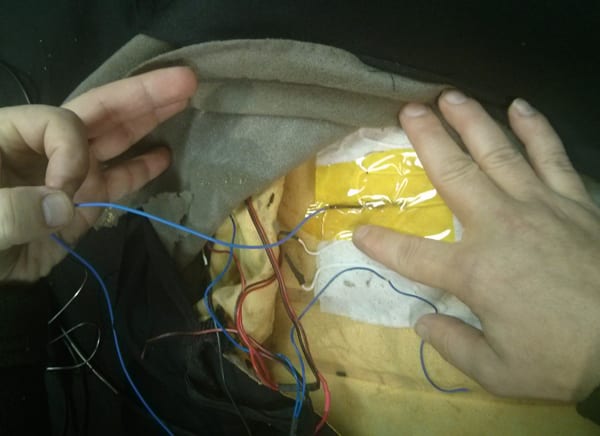

Dragging it into the lab, we peeled back the covers to discover the usual and not-so-usual suspects.

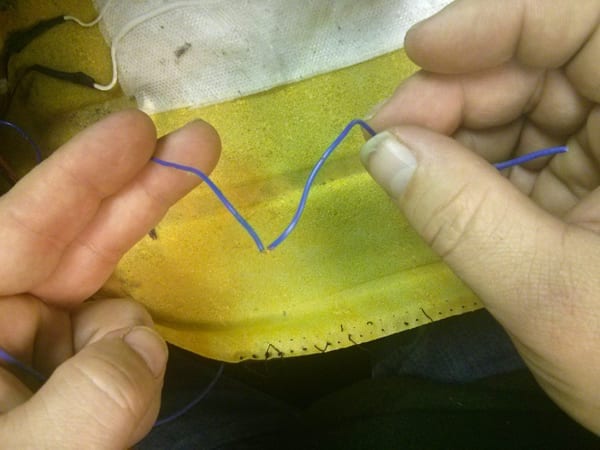

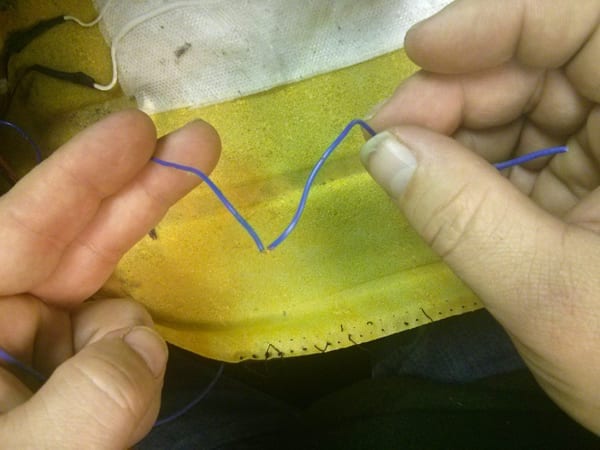

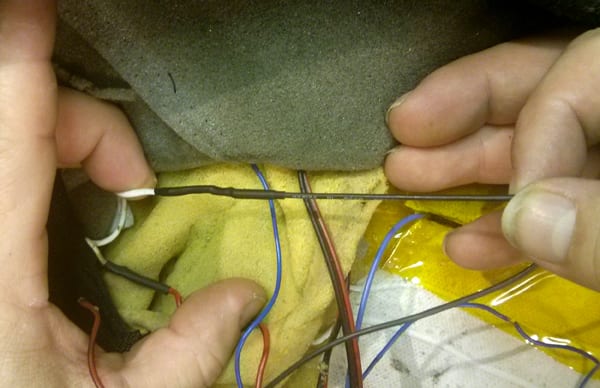

Broken wires:

The old wires had a PVC jacket that had dried out and cracked.

The wires would then flex at these cracks and break:

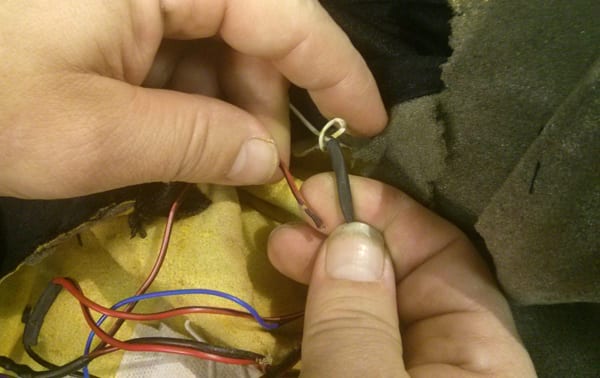

We replaced those wires with our GroovyNoodle silicone wire, which is able to resist flexing and temperature fluctuations very well.

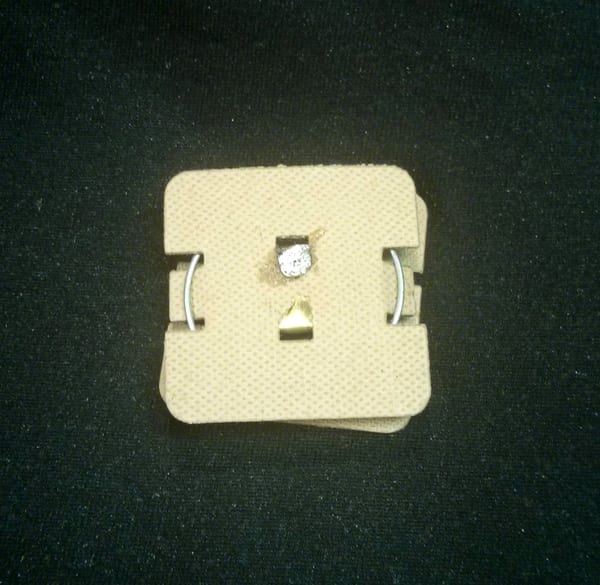

Sketchy Safety?

Here's a picture of the sketchy activation switch we found inside the bottom part of the seat. It's designed to close when under "bum load", and directly pass power to the heating coils. We're not experts at auto-grade accessory manufacturing, but we were surprised that it wasn't a logic "bum-detected" switch that triggered a suitable relay or FET elsewhere. And the lack of a thermal reset fuse surprised us.

Repaired

All broken wires replaced! Almost all the PVC jacket wire had cracked and disintegrated, so we replaced it with our better-quality GroovyNoodle silicone wire. This wire is extremely flexible, high strand count, and a temperature-ignoring silicon jacket. Perfect for inside this car seat heater.

All necessary repairs and upgrades were done just in time for the next stretch of (very much) cold Canadian winter.

MORE POSTS

We're not really into horoscopes that much, but generally we try to keep the company stars aligned. Sometimes, though, the stars do not align, and decided to go on spontaneous day trips to other corners of the galaxy. It's all well and good for the stars, but the planets really get confused and end up […]

It comes to our attention from J Wolfgang Goerlich that he won the ECRG Walker competition with the "Servocore Walker" he built from a project in our "Bicore Experimenter's PCB" bundle! See more details about his walker here.

We've had these for sale for a week now, and I haven't posted any news about them yet? What am I thinking? Ah, we were getting ready for the WCRG... never mind! Anyways, we've got these cool 6mm diameter 25:1 planetary gear motors now. They're smaller than our standard RPM2 pager motors! We've built a […]

Solarbotics, Ltd. is not responsible for misprints or errors on product prices or information. For more information, please see our Terms and Conditions.

Warning: This product contains chemicals known to the State of California to cause cancer and birth defects or other reproductive harm.

Please visit www.P65Warnings.ca.gov for more information. This item was manufactured prior to August 31, 2018.